Innovation

«Climate and environment focused innovation»

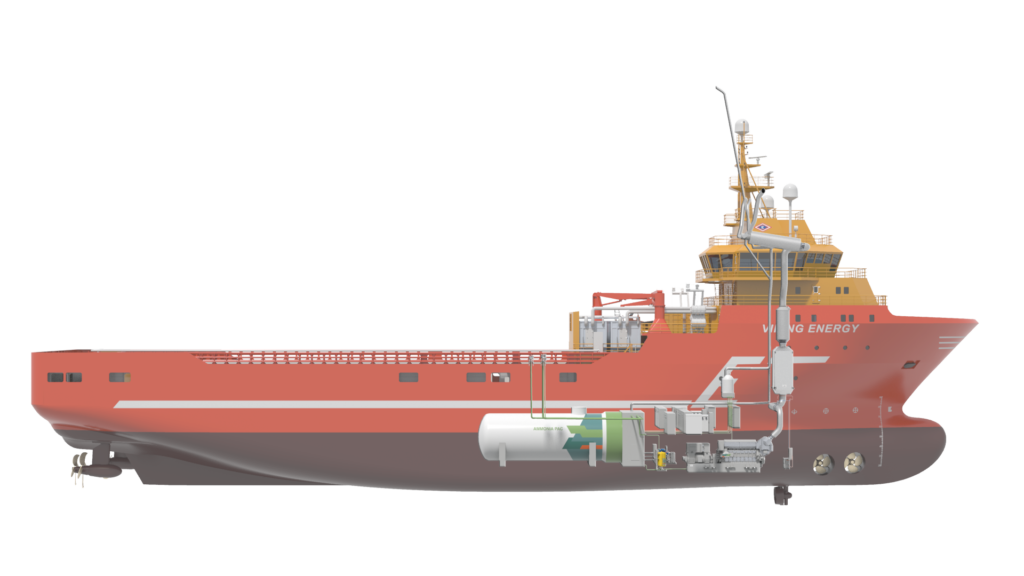

Our success story of climate and environment focused innovation started back in 2000, when the first plans for LNG operation of a PSV were formed within our company. With the delivery of Viking Energy in 2003, Eidesvik became the very first to introduce LNG as fuel for offshore vessels. By now, five of our PSVs are operating on LNG dual fuel.

The next chapter was written between 2006 and 2012, with the early full-scale testing of fuel cell technology, and later also the pioneering implementation of a battery hybrid system, onboard our PSV Viking Lady.

Partly in parallel to this, we started up the Eidesvik Energy Efficiency Program (EEEP) as early as 2010, with full implementation by 2014. This program gave us not only a significant reduction in fuel consumption and emissions (10% reduction from operational measures only), but also valuable added insight in our vessels’ operations. This insight has been crucial in finding the perfect solutions for improvements together with our clients and suppliers, and whether it comes to cost efficient solutions, purpose-built design, improvements on route planning or operations planning, the long-term logging of operational data is a key element.

Probably more important than anything, we built further on the engagement and focus through all parts of our organization, where everyone in the company now shared goals in saving fuel, reducing emissions and contribute to innovation. We then had the platform to bring our innovation story yet another step forward.

With loads of operational data, a team of already very engaged personnel offshore and onshore, and a set of full-scale results from the testing onboard Viking Lady, we started the commercialization of battery hybrid systems for offshore use. First with Viking Queen in 2015, then peaking with the world’s first “Battery Power” notation given to Viking Energy in 2016, followed by the disruptive innovation of replacing a generator set with a battery system onboard Viking Princess in 2017. In 2019 we also brought batteries to the construction vessel segment by converting Seven Viking from diesel-electric to battery hybrid propulsion. At present we are in the process of installing our battery hybrid systems number six and seven onboard Viking Neptun and Viking Avant.

These technology improvements, together with a series of others – such as hull design, combinations of different engine sizes etc., have over the years given a significant contribution to our fuel consumption trend continuously pointing the right direction.

Our EEEP program is still as vital as ever. With our long-term focus and steady strategy on climate, environment and fuel saving for 20 years, we have managed to establish a company culture not only focused on technology, but also on the operational side of fuel and emission reductions. All activities have been thoroughly logged for eight years now, giving us vast datasets to support further improvements both on operations and technology. A set of measures to reduce consumption and emissions have been defined and implemented throughout the fleet – without compromising on safety. We have quarterly meetings with key personnel onboard each vessel, analyzing the trends together and bringing new knowledge again and again to each vessel and to the fleet in general. No technical solution or tool can deliver better than the limits of its operator, thus we are proud to say that our operators really holds the skills necessary.

In 2020 we entered into the joint development project “ShipFC” where the aim is to convert our PSV Viking Energy to operate with a 2 MW fuel cell that can run on green ammonia, and thus significantly reduce the emissions of the vessel – again. Backed by the EU we kicked-off another groundbreaking project in 2023; project “Apollo”. In “Apollo” we have joined forces with key partners Equinor and Wärtsilä to install an ammonia combustion engine in Viking Energy in 2026. The aim is to reduce the vessel’s emissions by 70 percent or more. Another world’s first for our Viking Energy, proving that it is always possible to take a next step towards perfect.

Being first with LNG, “Battery Power” notation and ammonia, VIKING ENERGY, has and will be one of the key players in the Eidesvik success-story of climate and environment focused innovation. By her 25th anniversary she will have reduced emissions by 83-98% and fuel consumption will be reduced with 42%.

Fuel and emission reductions is a part of Eidesvik main strategy, and there will always be room for further improvements. We have been – we are – and we intend to remain – an arrowhead in that process. Our innovation story has not come to an end!